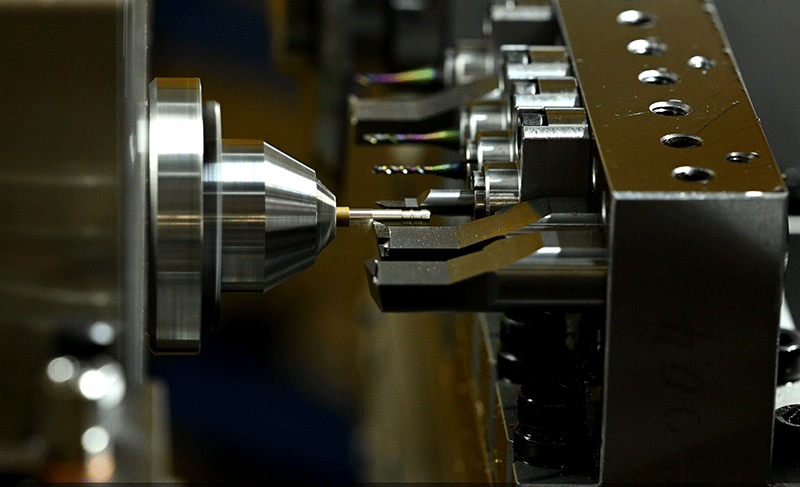

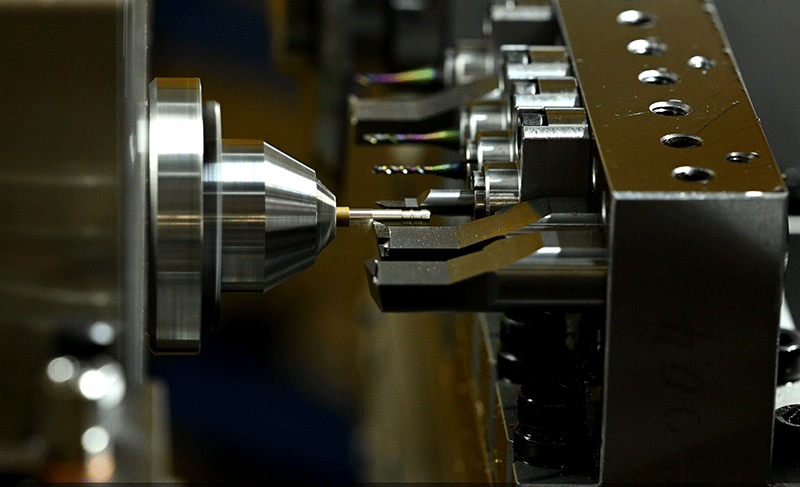

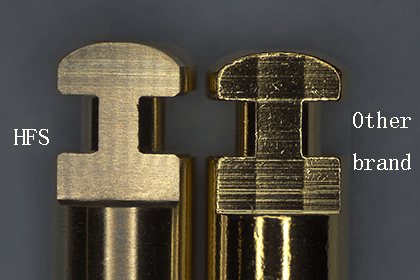

Precisio Craftsmanship

Reliable Choice

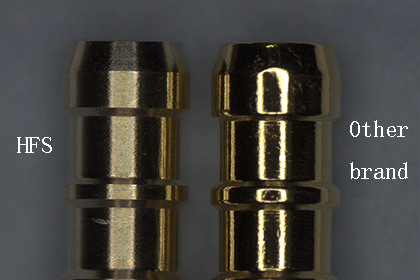

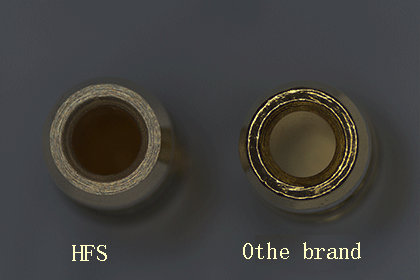

Next-Generation High-Precision

Root Canal File Handle

Next-Generation High-Precision

Root Canal File Handle

| Inner diameter | Outer diameter | Channel width | Flat dimension | Roughness | Coaxiality of Inner and Outer Circles |

|---|---|---|---|---|---|

| ±0.005 | ±0.003 | ±0.005 | ±0.008 | Ra0.4 | 0.005 |